Sustainability practices have traditionally referred to a product’s end of life recyclability. However, businesses are ever increasingly adopting a whole process or life-cycle approach. Whereby they are incorporating sustainable options into their entire supply chain, whilst simultaneously adopting eco-friendly practices within their organisation. This has seen a shift from what has at times been seen by many as just a box ticking exercise. Marking a transition to an embracement of overall sustainability considerations in company culture and business ethics.

Certainly, there are a range of sustainability frameworks available that organisations can use as a lens to look through when auditing their production and practices. Alongside an assortment of sustainability certifications and ISO standard ticks in recognition of “compliance”. Be that as it may, there is an increasing rise in organisations embracing sustainability practices into their entire business eco-system. Enabled in theory with education and in practice with sustainable eco-friendly practices and materials.

Sustainability Perception

Historically, sustainability has had the perception of relevance to ‘end of life’ for products. Which, is a positive step towards reducing waste from the final disposal of products. However, there are countless other opportunities along the value creation chain to implement more sustainable practices and material usage. The embracement of which marks a shift towards ethical care in decisions on quality and also world impact. Just as corporate social responsibility focuses on helping people, it could be said that sustainability responsibility focuses on helping the environment. Not to mention consideration for future generations.

Fortunately, a new perception of sustainability practices around whole process or life-cycle appreciation is gaining traction and value. With some organisations building sustainability factors into the tender process and accompanying buying decisions.

The Three R’s of Sustainability

A common phrase used in discussion around sustainability is RECYCLE > REDUCE > REUSE. Having long been the mantra of sustainability managers and the eco conscious. However, if we look at these factors objectively we may ask ourselves “Are we doing enough?”

Reduce

Production methods should aim to reduce the amount of wastage by getting the maximum use of raw materials per metre, thus minimising total resource need and cost. Alongside a policy of only using what is necessary to protect from damage and prevent soiling in transit and storage until the product is installed or used.

Reuse

Alternatively, packaging that is reusable may also be an option that outlasts recycled material packaging many times over. Add to that a reduction of materials to only what is required and the use of recycled materials where possible and you are factoring in sustainability on three different levels.

Recycle

Although a worthy cause, recycling disappointingly results in only 9.4% of plastics and 60% of paper and cardboard actually being recycled in Australia at this point in time, with the rest going to landfill. Even so, the more recycling the better and most definitely some is better than none. Additionally, using recycled products completes the cycle by reducing the overall carbon footprint.

Time for a Re-think and Re-design

Whilst recycling, reducing and reusing are all positive steps towards sustainability. As transport and packaging options evolve it may be time for a re-think and re-design. Not only looking at waste, going that eco-step further to utilise materials that are either made from recycled materials or drawn from sustainable resources. Notably, 70% of environmental impact from packaging can be attributed to the design phase. But what about the production of that packaging and transportation, can packaging redesign and more eco-friendly options also make an impact?

As an example, Armitage Group through an audit of transportation and packaging of our Tunnel Message Signs, had a re-think about how we could reduce the amount of waste and fit more product crates per container. By embracing innovation, the decision was made for a re-design of the product packaging to reduce the overall volume each unit occupied. This allowed savings in freight, less packaging and hence waste, resulting in a positive impact on the environment.

A dedication to enhancing sustainability throughout the entire business eco-system will require a small degree of trial and error. At Armitage Group we aim to consider using more sustainable and eco-friendly solutions on an ongoing basis. Designing and trialling variations, adapting when suitable and continuing to evolve. With this intention, in conducting our sustainability audit we found ourselves asking “How far can we go with sustainability considerations?”

Burden or Incentive?

This brings us to the dilemma of whether from a commercial perspective, sustainability is a burden or incentive? Appreciating that a business has to make a profit, costs must be minimised to acceptable levels appropriate to quality. However, if the purchaser has a adopted a sustainability policy, that stipulates to source products where possible that incorporate sustainability measures into their design, then adoption of sustainable products and processes as a supplier transitions from a ‘burden’ to an ‘incentive’.

To elaborate, this may include sustainable practices and considerations, such as the creation and adoption of a sustainability policy, the use of sustainable materials and even the mode of transport. Providing a broader incentive to look at the entire value creation chain from raw product, manufacture, transport, storage, delivery and even installation.

Product Design Considerations

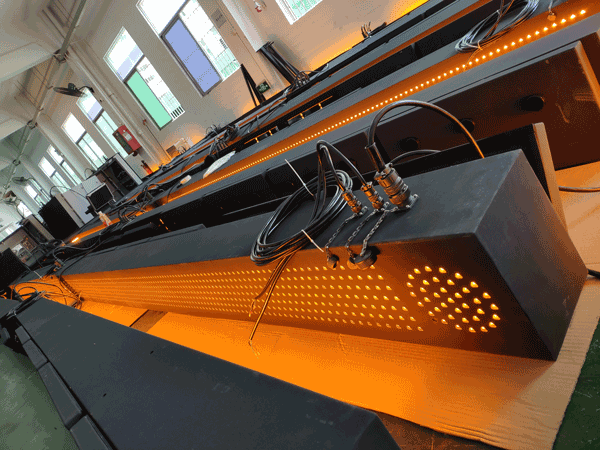

Creating a product that is high quality and has considerations to extend service life also falls into a sustainability consideration. As an example, Armitage Group’s LED Signs specifically use a punch holed front panel to protect the polycarbonate from deterioration whilst giving enhanced optical performance.

An Entire Eco-System Approach

As can be seen, sustainability can be a choice covering the product, processes and elements in the entire supply chain. Increasingly, sustainability is becoming a shared responsibility of both the maker/supplier and the consumer/purchaser. Where working together in a co-creation approach to ensure sustainability considerations are implemented where possible, will make a positive impact on the environment.

Of course we should aim to remove toxic or hazardous materials wherever possible. This is where powder coating wins over painted finishes. As paint usually requires solvents, thinners and other hazardous materials in both production and application. Whereas powder coating involves the powder medium applied electrostatically and bonded with heat to provide a durable and protective finish.

Granted, completely reusable eco-friendly choices are extremely rare. At the same time, moving towards continuous improvement regarding sustainability means creating a closed loop where possible. To not only prevent wastage, but also future impact on the next generation and beyond.

The Power for Change

The power for change lies in an adoption decision for both the consumer and supplier. Although it has been shown that the choice of a sustainability considerate option is somewhat ambivalent for a non-direct user, a direct user may demonstrate increased consideration when sustainability measures resonate with them or when they are part of a contractual or tender obligation.

With attention to shared responsibility and mutual benefit, for the purchaser who has a policy of acquiring sustainability considerate products, the acquisition of such can in turn enhance their own sustainability compliance. This highlights how the choices of one business can have multiple positive effects up and down the supply chain.

In the long run, an entire eco-system approach to sustainability can have many positive effects, and the more that is done the more the environment is protected. If you take the time to audit your organisation, production and processes, opportunities will appear. Not just as a box ticking exercise, but as an opportunity for improvement. We all have a choice, and together we can create incentives, encourage compliance and look forward to an ever increasing sustainable future.